Monocrystalline vs. Polycrystalline Solar Panels?

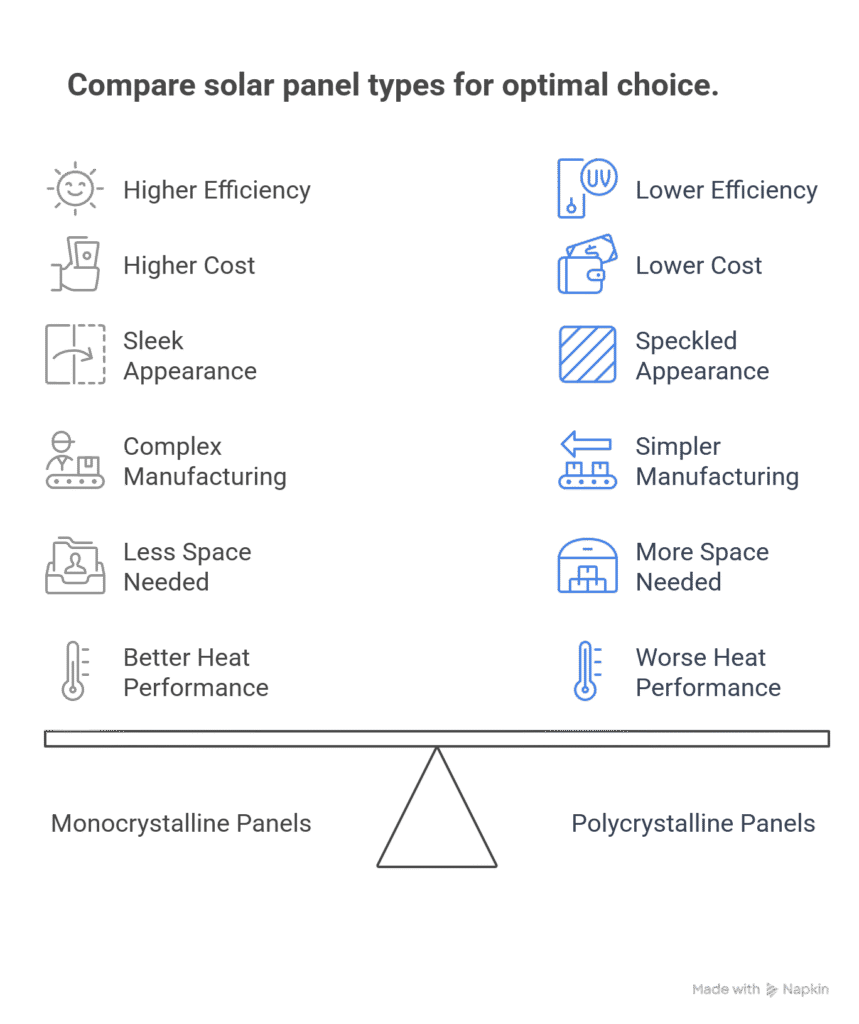

Monocrystalline and polycrystalline solar panels differ primarily in their manufacturing process and efficiency. Monocrystalline panels are made from a single, pure silicon crystal, giving them a uniform black appearance and higher efficiency rates, typically between 17% and 22%. They perform well in limited space and under low-light conditions, making them ideal for urban rooftops. However, their advanced production process often results in a higher upfront cost compared to other panel types.

Polycrystalline panels, on the other hand, are made from multiple silicon fragments melted together, resulting in a blue, speckled look. While their efficiency is slightly lower, averaging between 15% and 17%, they are more affordable and still perform reliably in Thailand’s abundant sunlight. In tropical conditions, the difference in performance between the two is often minimal, meaning the choice largely depends on budget, available space, and individual energy needs for homes or businesses.

Monocrystalline and Polycrystalline Solar Panels: What’s the Difference?

Monocrystalline solar panels are made from a single, pure silicon crystal, giving them a uniform black appearance and higher efficiency. Because the electrons have more room to move freely within the single crystal, these panels can convert sunlight into electricity more effectively. They also tend to perform better in low-light conditions and have a longer lifespan, making them ideal for homeowners with limited roof space who want maximum power output. However, the manufacturing process is more complex and expensive, which increases their overall cost.

Polycrystalline solar panels, on the other hand, are made by melting together multiple fragments of silicon, resulting in a speckled blue appearance. While they are generally less efficient than monocrystalline panels, they are more affordable and easier to produce. Polycrystalline panels are a popular choice for larger installations where space is not an issue and cost efficiency is a priority.

| Feature | Monocrystalline (Mono) Panels | Polycrystalline (Poly) Panels |

|---|---|---|

| Cell Composition | Made from a single, pure silicon crystal. | Made from multiple silicon fragments melted together. |

| Appearance | Uniform, sleek dark black colour. | Speckled or marbled blue appearance. |

| Efficiency Range | Higher: Typically 17% to 22% (Some newer models up to 24%). | Lower: Typically 15% to 17% (The article notes this is a more affordable trade-off). |

| Cost per Watt (THB) | Higher: Approximately 25 to 40 THB per watt. | Lower: Approximately 18 to 30 THB per watt. |

| Performance in High Heat | Better Temperature Coefficient. Efficiency degrades less than Poly panels as temperatures rise above 25°C. | Less Sensitive/More Stable. Provides more stable output under high heat conditions, though efficiency is lower overall. |

| Degradation Rate | Slower: Around 0.3% to 0.5% loss of output per year. | Faster: Around 0.5% to 0.8% loss of output per year. |

| Best for Limited Space | Yes (Preferred). Their higher efficiency means you need fewer panels to meet your energy needs. | No. Their lower efficiency means you require more panels and greater roof area for the same output. |

| Overall Value Proposition | Higher upfront cost but superior long-term performance and energy yield, often leading to a quicker and greater Return on Investment (ROI). | Lower initial cost and a practical, reliable choice for properties with large, unshaded roof space and tighter budgets. |

Efficiency of Monocrystalline vs Polycrystalline Panels

Monocrystalline solar panels are known for their high efficiency, typically ranging from 17% to 22%. They are made from a single continuous crystal structure, allowing electrons to move more freely and generate electricity more effectively. This results in better performance under low-light conditions and higher power output per square meter. Because of their superior efficiency, monocrystalline panels are ideal for residential or commercial installations with limited roof space where maximising energy production is a priority.

Polycrystalline solar panels, in contrast, are manufactured from multiple silicon crystals melted together, which creates boundaries that slightly reduce efficiency—usually between 15% and 17%. While they produce less energy per unit area, they are more cost-effective to manufacture and install. Polycrystalline panels still provide consistent, dependable performance and are a practical choice for projects with ample installation space or for users seeking a balance between efficiency and affordability.

Cost of Monocrystalline vs Polycrystalline Panels in Thailand

In Thailand, the cost of solar panels can vary depending on the type, quality, and supplier. Monocrystalline panels typically range from 25 to 40 baht per watt, making them more expensive than polycrystalline options. This higher price is mainly due to the more advanced manufacturing process and the panels’ greater efficiency in converting sunlight into electricity. For homeowners or businesses with limited roof space, the improved performance of monocrystalline panels can justify the higher initial cost, as fewer panels are required to meet energy needs.

Polycrystalline panels, on the other hand, are generally priced between 18 and 30 baht per watt, offering a more budget-friendly solution. Their lower efficiency means that more panels may be needed to produce the same output as monocrystalline ones, but for installations with abundant space, this is rarely a problem. This affordability makes polycrystalline panels a popular choice for large-scale or rural solar projects in Thailand.

Performance in Thailand’s Tropical Climate

Thailand’s tropical climate, marked by high temperatures, intense humidity, and strong sunlight throughout the year, greatly influences the performance of solar panels. The heat and consistent exposure to UV radiation can affect energy conversion efficiency and long-term durability. Monocrystalline panels, known for their high efficiency and sleek design, generally achieve the best performance under moderate temperatures and direct sunlight. However, in Thailand’s heat, their efficiency can slightly decrease as temperatures rise. Recent innovations, such as improved cell architecture and heat-dissipating materials, have significantly reduced this drawback, making them increasingly viable in tropical environments.

Polycrystalline panels, on the other hand, are less sensitive to temperature changes and provide more stable output under high heat conditions. Although they typically have a lower efficiency compared to monocrystalline panels, their reliability and cost-effectiveness make them suitable for Thailand’s conditions. The choice often depends on budget, installation space, and the desired balance between efficiency and performance stability.

Choosing Solar Panels for Limited Space

For homeowners or businesses with limited roof space, choosing the right type of solar panel is crucial to maximise energy production. Monocrystalline solar panels are often the preferred option because of their high efficiency and sleek design. These panels are made from a single continuous crystal structure, allowing them to convert more sunlight into electricity compared to other types. This means you can achieve the same power output with fewer panels, making them ideal for small rooftops or compact installations.

Additionally, monocrystalline panels tend to perform better in low-light conditions, providing consistent energy generation throughout the day. Although they may cost more upfront, their durability and long lifespan make them a worthwhile investment for space-constrained properties. Pairing these panels with efficient inverters and battery storage systems can further enhance performance, ensuring reliable renewable energy production even when roof space is limited.

Best Solar Panels for Thailand’s Hot Climate

Thailand’s abundant sunshine provides excellent conditions for solar energy generation, but the country’s high temperatures can affect panel efficiency. When choosing the best solar panels for Thailand’s climate, it’s important to consider both performance and heat tolerance. Monocrystalline panels are known for their high efficiency and sleek design, making them ideal for areas with strong sunlight. They perform well in high insolation conditions, delivering more power output per square meter compared to other types.

However, in regions where heat levels remain consistently high, polycrystalline panels may offer better long-term reliability. Although they are slightly less efficient, they tend to handle higher temperatures more effectively, maintaining steady output and durability. Some homeowners and businesses also opt for advanced half-cut cell or bifacial technologies, which further improve energy generation and heat management. Overall, selecting the right panel type for Thailand’s hot climate can ensure both optimal performance and long-term energy savings.

Degradation Rate of Solar Panels in Hot Climates

Solar panel degradation is a natural process that gradually reduces the energy output of the panels over time. In hot climates, this process tends to accelerate due to prolonged exposure to high temperatures and intense sunlight. Heat can cause thermal stress on the photovoltaic cells, leading to microscopic cracks and material fatigue. UV radiation also contributes to the breakdown of encapsulant materials and discoloration, both of which reduce overall panel performance and lifespan.

The degradation rate varies depending on panel type and manufacturing quality. Monocrystalline panels generally degrade at a slower rate—around 0.3% to 0.5% per year—compared to polycrystalline panels, which can degrade at about 0.5% to 0.8% annually. Over 25 years, this difference can significantly impact energy production and financial returns. In hot regions, choosing high-quality panels with heat-resistant materials and proper ventilation can help mitigate degradation and maintain higher efficiency over time.

Temperature Coefficient and Its Effect on Solar Panel Performance

The temperature coefficient of a solar panel indicates how its efficiency changes with temperature. As the temperature increases, the panel’s electrical output decreases because excessive heat reduces the voltage generated by the solar cells. The coefficient is expressed as a percentage loss per degree Celsius above 25°C, the standard testing temperature. For example, a coefficient of -0.4%/°C means that for every degree above 25°C, the panel’s efficiency drops by 0.4%.

Both monocrystalline and polycrystalline panels have temperature coefficients, but polycrystalline types generally handle heat slightly better. This makes them suitable for tropical regions like Thailand, where temperatures frequently exceed 30°C. However, monocrystalline panels, despite being more sensitive to heat, usually provide higher overall efficiency and better power output in most conditions. Therefore, while polycrystalline panels can be more stable in hot climates, monocrystalline panels remain the preferred choice when maximum performance is the main priority.

Cost vs Efficiency: Finding the Balance

When choosing between monocrystalline and polycrystalline solar panels, it’s important to consider both cost and efficiency to achieve the best value. Monocrystalline panels are made from a single crystal structure, allowing them to convert sunlight into electricity more efficiently. They perform better in low-light conditions and take up less space, making them ideal for homeowners with limited roof area or those looking for maximum energy output. However, this higher performance comes with a higher upfront cost, which may not suit every budget.

Polycrystalline panels, on the other hand, are made from multiple silicon fragments melted together, resulting in slightly lower efficiency. They generally require more surface area to produce the same amount of energy as monocrystalline panels but come at a more affordable price. This makes them a practical choice for those with larger installation areas or tighter budgets, offering a solid balance between performance and cost-effectiveness.

Solar Panel Installation Costs in Thailand

The cost of installing a solar system in Thailand varies widely based on several factors, including the type of solar panels, system capacity, installation complexity, and regional labour rates. Monocrystalline panels, known for their high efficiency and sleek design, typically come with higher upfront costs due to more advanced manufacturing processes. In contrast, polycrystalline panels are generally cheaper to produce and install, making them an attractive option for homeowners or businesses looking for a cost-effective renewable energy solution.

Additional factors influencing installation costs include roof type, mounting structure, inverter quality, and wiring requirements. In urban areas such as Bangkok or Chiang Mai, labour costs may be slightly higher than in rural provinces. On average, residential solar installations in Thailand range from 35,000 to 60,000 THB per kilowatt, depending on system size and component quality. Larger systems benefit from economies of scale, reducing the cost per kilowatt installed.

Long-Term Energy Savings with Solar Power in Thailand

Investing in solar energy in Thailand offers substantial long-term financial benefits, as the country’s abundant sunlight allows for efficient power generation throughout the year. By harnessing solar power, homeowners and businesses can significantly reduce their dependence on grid electricity, leading to lower monthly utility bills. Over time, these savings can offset the initial installation costs, making solar energy an increasingly attractive option for both residential and commercial users. Additionally, government incentives and declining solar equipment prices continue to enhance the overall return on investment.

The extent of your savings depends on the type and efficiency of the solar panels installed. Monocrystalline panels, known for their high efficiency and durability, typically deliver greater energy output and faster payback periods. However, polycrystalline panels remain a practical choice for those with larger installation areas, offering reliable performance at a lower cost. With proper design and maintenance, solar systems can provide consistent savings for decades.

Solar Panel Warranties and Lifespan

Solar panel warranties provide assurance of long-term performance and durability. Both monocrystalline and polycrystalline solar panels usually come with warranties ranging from 20 to 25 years, covering performance and manufacturing defects. These warranties guarantee that the panels will maintain a certain percentage of their original efficiency, ensuring consistent energy production over decades. The length and quality of the warranty are key indicators of a manufacturer’s confidence in the product’s reliability.

Monocrystalline panels generally have a longer expected lifespan and a stronger warranty compared to polycrystalline panels. Their higher purity silicon allows them to operate more efficiently and degrade more slowly over time. This results in better performance in low-light conditions and a more consistent energy yield throughout their lifetime. For homeowners and businesses seeking long-term energy savings and sustainability, monocrystalline panels are often the preferred choice, offering excellent returns on investment through efficiency and durability.

The Future of Solar Energy in Thailand

Thailand’s solar energy sector is entering an exciting phase of growth as technology becomes more advanced and affordable. Both monocrystalline and polycrystalline solar panels have improved in efficiency, allowing households and businesses to generate more power from the same surface area. With the falling cost of installation and maintenance, solar systems are now within reach for a wider segment of the population. These advancements are helping Thailand reduce its dependence on fossil fuels and lower greenhouse gas emissions.

Government support has been a major driving force behind this progress. Incentives such as tax benefits, feed-in tariffs, and grants encourage investment in solar energy projects. As Thailand aims to increase its share of renewable energy, solar power is expected to play a key role in achieving national sustainability goals. With continuous innovation and strong policy backing, Thailand is well-positioned to become a regional leader in solar energy adoption.

Final Thoughts …

While the debate between Monocrystalline and Polycrystalline panels often centers on efficiency and cost for standard grid-tied setups, this choice becomes even more critical when planning for energy independence. For homeowners looking to install a hybrid solar system that incorporates battery storage, the higher efficiency of Monocrystalline panels can be advantageous, as they maximize energy generation from a limited roof area, providing more power to charge the battery bank quickly. Furthermore, if your long-term goal is to go entirely off-grid for complete energy autonomy, selecting the most efficient panel type (Mono) is often recommended to ensure maximum power capture, reliability, and quicker payback on the entire system, especially where every watt counts.

When deciding between monocrystalline and polycrystalline solar panels, it’s important to assess your energy goals, available space, and budget. Monocrystalline panels offer higher efficiency and a sleek appearance, making them suitable for homes or businesses with limited installation areas. Although they come with a higher upfront cost, their long lifespan and superior energy production can provide greater returns over time.

On the other hand, polycrystalline panels are a practical and cost-effective choice for those prioritizing affordability without compromising reliability. They perform well under standard conditions and are ideal for larger properties with sufficient roof space. Considering factors such as Thailand’s warm climate, potential shading, and maintenance requirements will help you select the most suitable system. Ultimately, both options contribute to long-term energy savings and sustainability, allowing you to harness Thailand’s abundant sunlight efficiently while reducing dependence on conventional energy sources.

If you’d like to learn more or want a friendly chat obligation free then why not call us on +66 82 704 6939 or contact us today we will be happy to help

FAQs

Monocrystalline PV cells are made from a single, pure silicon crystal, offering higher efficiency and a uniform black colour. Polycrystalline solar cells are made from multiple silicon crystal fragments, which makes them more cost-effective but slightly less efficient.

Monocrystalline solar panels generally have a better temperature coefficient, meaning their efficiency degrades less than polycrystalline panels as temperatures rise above 25°C. This makes them a preferable option for the intense heat in Thailand.

Monocrystalline (Mono) panels are generally considered better for most homeowners and commercial applications due to their higher efficiency (typically 17% to 22%) and superior long-term performance. They produce more power per square meter, making them ideal when roof space is limited.

Polycrystalline solar panels are typically the more affordable option regarding the initial purchase cost, as their manufacturing process is simpler and uses less pure silicon.

Monocrystalline solar panels are recommended for limited roof space because their higher efficiency means you can generate more solar power per square metre, requiring fewer panels for the same energy yield.

Monocrystalline solar panels typically have an efficiency range of around 18% to 24%, which is among the highest for commercial PV technology.

Polycrystalline solar panels typically have a slightly lower efficiency range, often between 13% and 17%

Modern high-quality monocrystalline panels often perform better than polycrystalline panels in low light or cloudy conditions, making them ideal for areas with less consistent sun exposure.

Monocrystalline solar modules usually have a uniform, dark black colour, while polycrystalline modules have a speckled or marbled blue appearance.

Both types of PV panels typically come with a 25-year performance warranty, but monocrystalline panels, due to their higher-purity single-crystal structure, are often projected to have a slightly longer operational lifespan.

The temperature coefficient measures how much a solar panel’s efficiency drops for every degree Celsius rise above 25°C. A lower (closer to zero) coefficient is better for hot regions like Thailand.

The production of polycrystalline PV cells is generally considered to create less silicon waste than the production of the single-crystal silicon used in monocrystalline panels.

While high ambient humidity affects all solar panels, choosing a high-quality PV module with robust construction is more critical than the cell type to mitigate long-term moisture degradation in a tropical climate.

Yes, due to their lower efficiency, you will need a larger number of polycrystalline panels to achieve the same total power output as a monocrystalline solar array, thus requiring more roof space.

Monocrystalline panels are often preferred for off-grid solar systems where maximising the energy yield from a fixed, limited space is paramount.

While polycrystalline panels have a lower initial cost, the higher efficiency and superior long-term performance of monocrystalline panels in high temperatures can often lead to a quicker and greater return on investment (ROI).

Yes, the quality and efficiency can vary significantly between different manufacturers and product lines for both mono and poly PV technologies. It is important to check the panel specifications.

Monocrystalline panels are generally considered more aesthetically pleasing due to their sleek, uniform dark colour, which can blend better with modern rooflines.

Aside from efficiency, key specifications to compare include the temperature coefficient, the panel’s wattage output, and the annual degradation rate.

Yes, a polycrystalline solar power system remains a viable and more cost-effective choice for properties with large, unshaded roof space where maximising the initial investment is a key concern.

Newer monocrystalline designs, particularly with half-cut cell technology, can often handle partial shading better than traditional polycrystalline modules.

It is recommended to check local solar installation companies in Thailand that offer certified products and reputable warranties for both monocrystalline and polycrystalline solar array solutions. Here at Solar Panels Thailand we can of course can also help

Monocrystalline panels generally have a slightly longer effective lifespan and a better performance warranty.

- Monocrystalline Lifespan: Typically 25 to 30 years, with some premium models lasting up to 40 years. They have a lower annual degradation rate (around 0.3% to 0.5% loss per year).

- Polycrystalline Lifespan: Also typically 25 years. Their higher degradation rate (around 0.5% to 0.8% loss per year) means their power output drops faster than monocrystalline over the system’s lifetime.

Yes, you can mix monocrystalline and polycrystalline panels, but it is not generally recommended for optimal system performance, especially if they are wired in the same series (string).

If mixed, all panels in a single string will be limited by the lowest-performing panel’s voltage and current. To mix them efficiently, you must use Microinverters or Power Optimizers on each panel, or wire them into separate circuits using an inverter with multiple Maximum Power Point Tracking (MPPT) channels. This ensures each panel operates at its peak efficiency.

Yes, Monocrystalline panels are generally better in hot weather compared to traditional Polycrystalline panels. Their key advantage is a more favourable Temperature Coefficient, meaning their efficiency degrades less for every degree the panel temperature rises above the standard testing condition (25∘C). While all silicon-based PV cells lose some efficiency in high heat, Mono panels lose less, providing a consistently higher energy yield in tropical or very warm climates.

The 33% rule (or 133% rule) is a common electrical regulation (e.g., in some international codes) regarding inverter oversizing. It states that the total DC panel capacity (watts) connected to an inverter can exceed the inverter’s AC output capacity by a maximum of 33%.

For example, a 5 kW AC inverter can be connected to up to 6.65 kW DC of solar panels (5 kW×1.33=6.65 kW). This practice, known as oversizing or clipping, is intentional to maximize energy production during low-light periods (mornings, evenings, cloudy days), as panels rarely hit 100% of their nameplate capacity.

The average service lifespan for both monocrystalline and polycrystalline solar panels is 25 years. Most reputable manufacturers offer a 25-year performance warranty, guaranteeing the panel will still produce at least 80-85% of its original rated power by the end of that period. Monocrystalline panels often retain a higher percentage of their original output due to a slower annual power degradation rate.

You can mix different wattage solar panels, but it is strongly discouraged if they are wired in series. When different sized panels are connected in the same string, the entire circuit’s performance is limited by the panel with the lowest current (Amps), which is typically the smaller 100-watt panel. This results in the larger 200-watt panel operating inefficiently. The best practice is to wire panels with different wattages or models to individual Microinverters or Power Optimizers.

The “20% rule” in solar can refer to two separate concepts:

- System Sizing (Energy Need): A common recommendation to oversize your system by 20% to account for variations in weather, seasonal changes, and system degradation over time. (e.g., if you need 1,000 kWh/month, install a system capable of 1,200 kWh/month).

- Efficiency Benchmark: It is often used informally as a benchmark, indicating that high-quality, modern solar panels should have an efficiency rating of at least 20% or more.

Mixing different PV cell types is possible but must be done carefully, usually requiring a specialised inverter setup to manage the different voltage and efficiency characteristics of the panels.

The Monocrystalline (Mono) panel is generally considered the best type of solar panel for home use, for the following reasons:

- Highest Efficiency: Maximize energy production on limited residential roof space.

- Aesthetics: The uniform, dark black appearance is preferred by most homeowners.

- Longevity: Lower degradation rate ensures better performance over the 25-year lifespan.

Yes, installing a solar power system, particularly one utilizing high-efficiency monocrystalline panels, can significantly increase a home’s value. Studies have shown that homes with owned (not leased) solar panels often sell faster and for a higher price than comparable non-solar homes, with value increases averaging 4% or more. The perception of owning a high-performing, durable renewable energy system is a major selling point.

The biggest risk related to solar panels is typically improper installation or electrical hazards. For homeowners, this risk manifests as:

- Fire Risk: Poor wiring, faulty connectors, or low-quality components can lead to arc faults and fire. This is mitigated by professional installation and the use of modern safety features like Arc-Fault Circuit Interrupters (AFCIs).

- Roof Damage: Poorly sealed mounting hardware can lead to water leakage and long-term roof degradation.

- Performance Risk: Choosing a non-reputable installer or low-quality components can lead to system underperformance, preventing the system from achieving its calculated Return on Investment (ROI).

The disadvantages of monocrystalline solar technology include:

- Higher Initial Cost: The single-crystal production process is more expensive.

- Manufacturing Waste: The process of creating the single silicon crystal (ingot) results in more wasted silicon material compared to the block casting used for polycrystalline cells.

- Sensitivity to Shading: If even a small part of a monocrystalline panel is shaded, the output of the entire string (series) can drop dramatically, making the use of power optimizers or microinverters essential.

You can easily distinguish between the two cell types primarily by their visual appearance:

| Feature | Monocrystalline (Mono) | Polycrystalline (Poly) |

| Colour | Uniform Dark Black | Speckled Blue or Marbled |

| Cell Shape | Cells have rounded edges (corners are cut off) | Cells are perfectly rectangular/square (no cut corners) |

| Cell Composition | Single silicon crystal | Multiple silicon fragments |

Monocrystalline solar panels are designed to last a minimum of 25 to 30 years. The key factor is their performance warranty, which guarantees a high output (typically 80-85%) remains after 25 years. With proper maintenance, the physical panels and mounting hardware can often remain functional for 40 years or more.

The type of solar panel with the highest efficiency is the Monocrystalline panel, specifically those manufactured using advanced technologies like N-Type cells or Back-Contact (IBC) architecture.

- Current Commercial High: Modern premium monocrystalline panels can achieve efficiencies of 22% to 24.8%.

- General Mono Range: Standard monocrystalline panels typically range from 17% to 21%.

The disadvantages of polycrystalline (Poly) solar panels primarily stem from their manufacturing process, resulting in lower efficiency and reduced performance compared to monocrystalline (Mono) technology:

Lower Efficiency: The fragmented structure of the silicon crystals results in a lower typical efficiency range of 15% to 17%. This means they convert less sunlight into electricity than Mono panels, requiring more panels and greater roof area to achieve the same total power output.

Worse Performance in High Heat: Poly panels have a higher temperature coefficient, leading to a more significant drop in power output when the panel temperature rises above 25°C (Standard Test Conditions). This is a notable drawback in tropical or very hot climates.

Higher Degradation Rate: They experience a faster annual degradation rate (around 0.5% to 0.8% loss per year). Over the 25-year warranty period, this quicker efficiency drop results in a substantial loss of total lifetime power production.

Increased Space Requirement: Due to lower power density, a larger footprint is needed to generate the same wattage, making them a poor choice for small residential roofs or applications with limited space.

Aesthetic Appearance: The panels have a characteristic speckled blue or marbled look, which is often considered less modern and less aesthetically pleasing than the sleek, uniform black of monocrystalline panels.

This article nails the central dilemma perfectly: cost vs. space/efficiency. I think the key takeaway for anyone reading in Thailand is to first measure your available unshaded roof space. If you’re constrained, Mono is the only logical choice because that higher 22% efficiency lets you maximize every square meter. If your roof is enormous, then Polycrystalline becomes a highly competitive, budget-friendly option. I appreciate you focusing on the temperature coefficient too, as a stable output in this tropical heat is often more valuable than a high peak output that immediately drops when the temperature hits 40°C. Excellent breakdown of the Thai market specifics.

Interesting analysis and Good read Thanks!

I installed Mono panels last year and I can confirm what the article says about the appearance. The sleek, uniform black design looks fantastic on my villa roof—it just blends in, and the curb appeal is definitely improved. But more important than the looks is the performance during the low light hours, like early morning and late afternoon. My energy monitoring app shows they still kick out decent power even when the sun isn’t directly overhead, which is exactly where Mono panels win over Poly. The higher efficiency means my batteries get topped up quicker. For me, that little bit of extra efficiency every day really adds up over the years, making the initial investment worth every baht. 😉

Look, I get it, Mono is better. But I have a huge warehouse roof and a super tight budget. The difference in price between the two, especially when buying thousands of watts, is massive. I can get 5kW more system for the same price if I go with Poly. That extra power output, even at lower efficiency, is better than paying way more for the “best” panels. It’s about ROI. If I’m paying 10 baht less per watt, that saves me serious coin on a big project. You gotta be practical about these things. Good artical, but the cost section is the most important part for me! 🎉

Thanks for clarifying the temperature coefficient! I’m a student researching PV degradation in tropical environments and I was trying to find real-world cost comparisons. The table listing the approximate price per watt (18-30 THB for Poly) is extremely helpful for my financial modeling. It seems like Poly is the clear winner for cost-effective large-scale solar farms where land (or roof) is cheap, but Mono maintains its dominance for the urban residential market in places like Pattaya or Phuket. Can you follow up with a piece on the performance differences in low-light conditions during the heavy monsoon season? That’s another huge factor here.

Monocrystaline panels are totaly worth the extra money, esp. if you are tring to get off the grid one day. My system with Poly panels is ok but in the rainy season I wish I had more power coming in to charge the battery bank. I think people worry too much about the upfront cost and not enough about the lifetime of the system. I also think the black mono panels just look way better on the roof of a nice house, the blue ones look kinda old fashioned now. Great article!

I disagree a little bit about the heat. I live down south in Krabi and the heat here is brutal year-round. My installer convinced me to go Polycrystalline because of the stability and the slightly lower temperature coefficient. While I know I’m sacrificing a bit of peak efficiency, I’d rather have a more consistent, less degraded output over the full 25-year warranty period, especially considering how much cheaper the Poly panels were initially. I had a huge roof, so space wasn’t an issue at all. For big rural installs, Poly is still the best bang for your baht, hands down.

This article is super timely. I’m building a new shophouse in Bangkok and roof space is seriously limited. I was leaning towards the cheaper Poly panels, but after reading your breakdown on efficiency (17-22% for Mono vs 15-17% for Poly), it makes total sense to go Monocrystalline. The higher upfront cost is worth the extra power output since I simply can’t fit enough Poly panels to hit my energy needs. The table breaking down the cost per watt in THB (25-40 THB for Mono) versus the long-term ROI was the convincing factor. Great info!